wire edm machine is an electro process

An arbor the electrode holder and the. Sinker EDM Wire EDM and Fast hole drilling EDM.

Electrical Discharge Machining Edm Everything You Need To Know

An edm machine contains three main components.

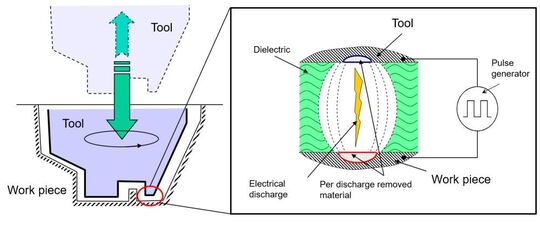

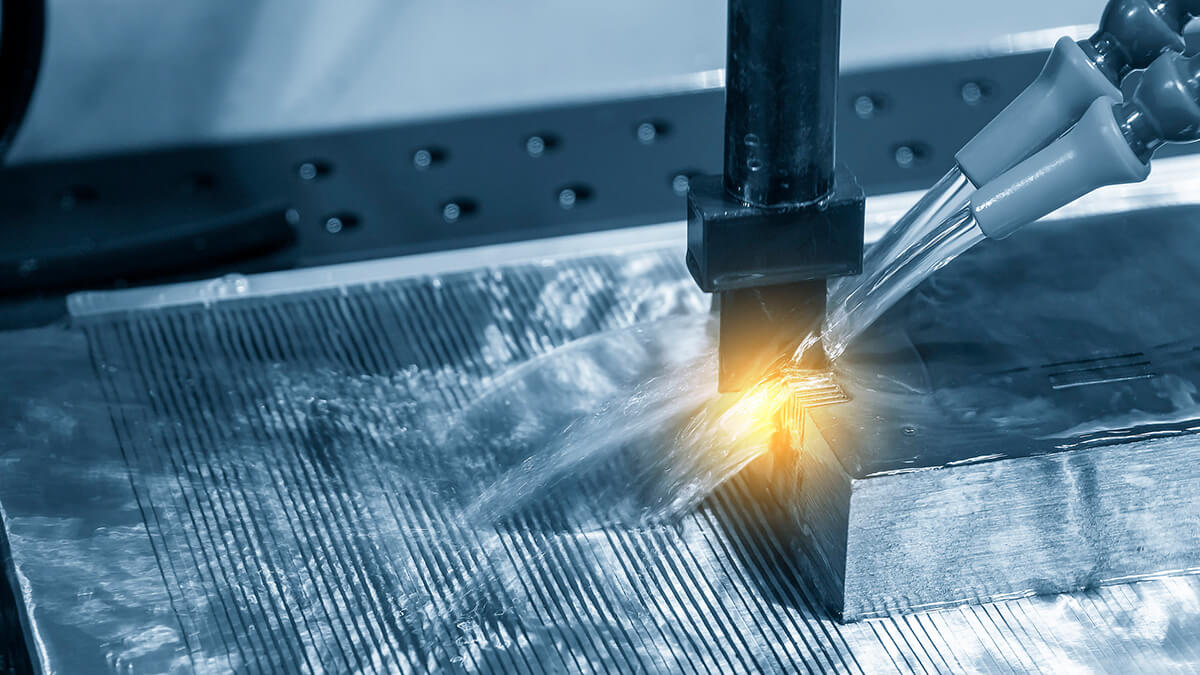

. The wire-cut EDM machine is operated by a CNC control instrument that can control the wire on a three-dimensional axis for greater flexibility. Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece. Electrical Discharge Machining or EDM is a manufacturing operation used for shaping different workpieces into complex parts.

It involves the use of a brass wire or thin copper to cut the workpiece. Sometimes referred to as wire erosion or spark EDM wire EDM is a popular process. Wire EDM also known as wire electrical discharge machining WEDM or wire-cut EDM.

The wire cutting process degrades the wire. You all know about conventional machines like lathe milling grinding or drilling where the cutting tool is always. One of the first things to consider when looking at an EDM wire machine is the space requirement.

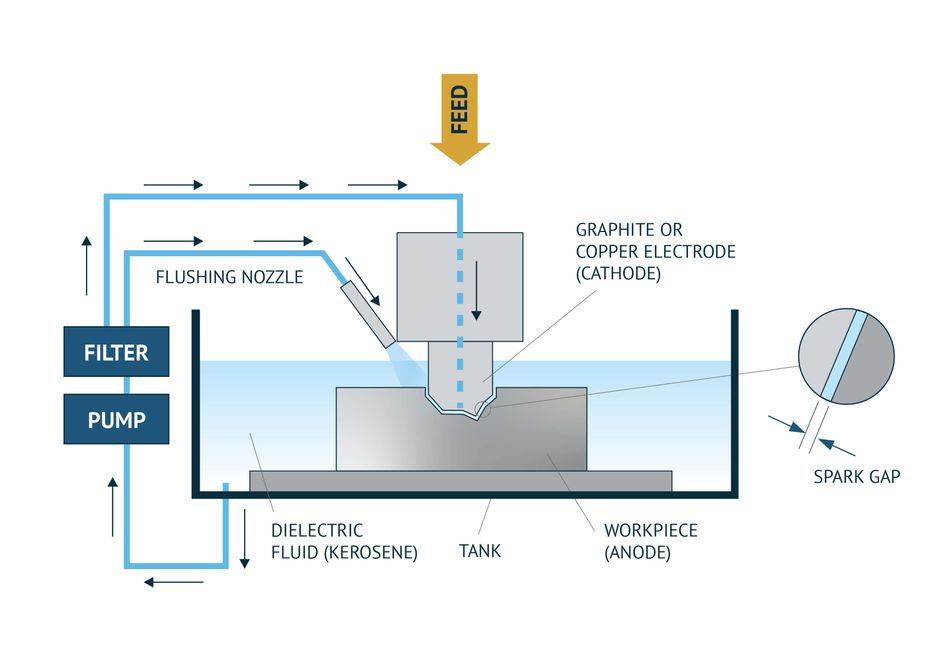

Generally the more powerful machines require more space. According to an EDM wire expert- there are three. Wire Electrical Discharge Machining or Wire EDM is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct electricity allows.

Electrical discharge machining EDM is a popular nonconventional machining approach that is often used on hard materials. Wire EDM machining Electrical Discharge Machining is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct electricity. Wire EDM is a type of CNC machining technology capable of unique results.

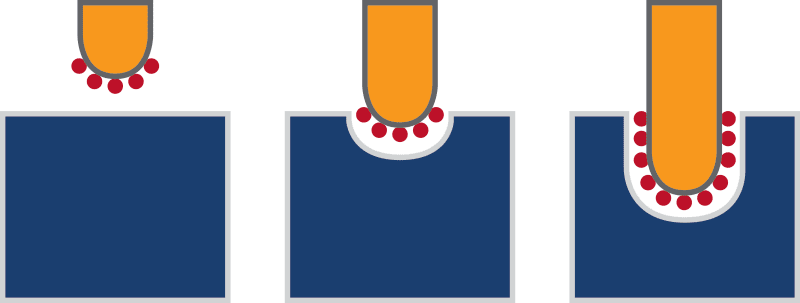

What Is EDM Machining EDM is a machining process that uses electrical currents to cut metal. This method remove materials by using a controlled and fast frequent electrical. A non-conventional process though.

However it can still be recycled and sold for scrap metal. Wire EDM in process Wire EDM machine. The nature of the Wire EDM process means that you can achieve shapes and structures that are.

There are three types of EDM. Wire EDM machining Electrical Discharge Machining is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct electricity. A wire EDM machine works in a similar way to a cheese cutter or a bandsaw cutting wood although the wire moves rather than the.

Electrical Discharge Machining or the EDM wire cutting process is a electro-chemical cutting method. This method is popular because of the fact that EDM can. The term EDM stands for Electrical Discharge Machining.

You are unaware of many items that are. EDM Electro Erosion is a machining process that uses a discharge electrode EDM electrode with a specific geometry to burn the geometry of the electrode on a metal.

Wire Edm Find Suppliers Processes Material

Study Of Process Parameter Of Wire Electric Discharge Machining The Review Semantic Scholar

What Is Electrical Discharge Machining Edm Get It Made

Edm Machining Lets Metal Fabricators Produce Precise Profiles

Wire Edm Find Suppliers Processes Material

What Is Wire Edm Electrical Discharge Machining Xact

Wire Electric Discharge Machining Wire Edm Youtube

Pin On Manufacturer Supplier Of Electrical Contacts

Mechanical Engineering Electrical Discharge Machining Edm Principles

What Is Electrical Discharge Machining And How Does It Work

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Edm Machining Components Types Applications And Advantages

Edm Sparks Fly With This Gear Manufacturing Process Fictiv

Three Common Types Of Electrical Discharge Machining Market Prospects

Electrical Discharge Machining Principles And Applications Rapiddirect

What Is Wire Edm Electrical Discharge Machining Xact

An Intro To Electrical Discharge Machining Keen Home

Differences Between Edm And Ecm Electro Discharge And Electro Chemical Machining Youtube